FORENSIC ENGINEERING AND EXPERT WITNESS SERVICES

2 March 2021

Table of Contents

What is happening on the claims side

It has been recorded in many recent publications that due to the disruption that COVID-19 has created in the construction industry in 2020, and so far in 2021, in certain locations the amount of disputes have doubled in comparison with previous years.

“COVID-19 and its effects have triggered many disputes, with litigation volumes in some jurisdictions having already doubled, and our clients expect us to help them spot trends and plan for the future”

In particular, Baker Mackenzie’s article titled ‘THE YEAR AHEAD: Developments in Global Litigation and Arbitration in 2021’ notes that:

“… construction is particularly dependent on international supply chains: materials shortages have occurred and costs have increased. Planning and inspection timetables have been delayed. New workforce safety measures have been introduced. We will see disputes around costs and delay . However, these are common in normal times, and the industry’s experience in finding quick, practical solutions to disputes will be useful.”

Figure 1 – Development in Global Litigation and Arbitration in 2021

Experience on claims and dispute resolution should be at the forefront of many companies’ priorities in order to move on. This is especially correct for forensic schedule analysis .

It is a given that COVID has been a disruptive event, however, in complex scenarios where force majeure clauses and related exclusions are in place, Contractors will have to find the best possible solutions to resolve direct and knock-on delays associated with the pandemic (e.g. affected procurement processes, affected financials, affected availability of resources, affected site HSE procedures, and the list goes on), and quite importantly, ways to protect their cash flow.

Construction Industry

Similarly, the construction industry as a whole will require all stakeholders to work together to find the best solutions to mitigate the negative consequences of the pandemic as much as possible. This all sounds very reasonable, but in circumstances where the relationship between the companies was not in a good place before the pandemic started, will not necessarily find a clear and easy path to resolve the new problems generated on the back of COVID.

Insurance Claims – Delay to Start Up (DSU)

We are aware that many new insurance policies, even on Delay to Start Up cases, will exclude COVID related claims, however, a forensic eye would be required in order to ascertain the conditions and status of a project before COVID, and ascertain if a project was already in delay before COVID, and under what circumstances the project would have been completed ‘but for’ COVID.

As international brokers Willis Towers Watson noted on their article “Construction insurance market update – the reaction to COVID-19”:

“ On several projects which have experienced a cessation of works, or significant slow-down, we have been asked to notify potential claims under the Delay in Start Up (DSU) section. This is interesting in its own right as the trigger for the delay generally needs to be a delay caused by a loss or damage event under the contract works section. But, we have placed many projects with broad policy coverage and some element of cover for delay caused by notifiable disease, and there is also the potential trigger of a denial of access ”

Manufacturing affecting Construction

There will be claims due to breach of contract on the back of COVID related delays during the manufacturing and delivery of, for example, equipment for large energy sites. Needless to say, a power plant cannot generate power without turbines, generators, transformers, and other complex long lead items. This would in turn lead to potential penalties for not producing power into the contracted grid, and could in turn lead to power supply issues. We can now see the knock-on effect on the back of COVID related delays.

It is also certain that since the litigation volumes have doubled in certain locations, that delays in these processes (which are inherently slow, even Alternative Dispute Resolution) will have their own knock on effect on the projects when contractors run out of ‘steam’. For instance, in cases where a contractor abandons a plant, the re-work required by the plant owner becomes both cumbersome and uncertain. This itself could generate more anxiety, more complications, and in turn, more delays.

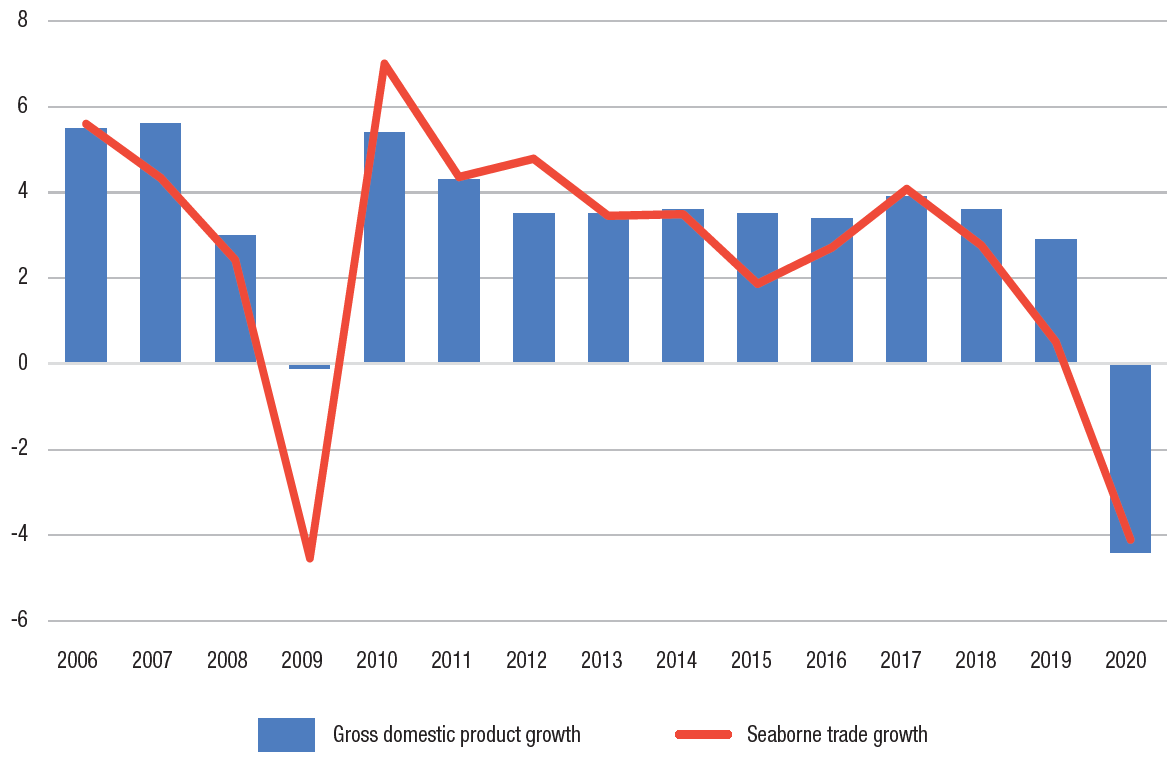

Shipping

Simply put by the United Nations Conference on Trade and Development (UNCTAD):

“The pandemic has sent shockwaves through supply chains, shipping networks and ports, leading to plummeting cargo volumes and foiling growth prospects”

Source: https://unctad.org/news/covid-19-cuts-global-maritime-trade-transforms-industry

Figure 2 – Shipping industry disruption through COVID times

Oil and Gas Industry

If we go to the Oil and Gas industry specifically, since the first period of the pandemic in March 2020, it suffered the lowest crude oil prices since the late 1990’s. For example for West Texas Intermediate (WTI or NYMEX):

Source: https://www.macrotrends.net/1369/crude-oil-price-history-chart

Figure 3 – Oil trends since the 1990’s – Extreme reduction of oil prices in 2020 which lead to project cancellations and delays

With an industry that was already recovering from the 2015 low oil prices, learning, and adapting to numerous environmental policies and CO 2 emission regulations, the pandemic certainly has had its effect. Of course, the use of hydrocarbons as a source of energy will continue for various decades, and the recent recovery of the oil prices will provide a much needed impulse.

Nuclear Industry

However, we wonder what is going to happen with the nuclear industry.

An article by MIT mentions that:

“For decades, the cost of building a nuclear power plant in the United States has been far higher than projected—one factor that has limited the expansion of this carbon-free electricity source. MIT researchers have developed tools that industry personnel can use to improve their cost projections and to predict how design changes will affect overall costs”

Source: https://energy.mit.edu/news/building-nuclear-power-plants/

Figure 4 – Delays in the Nuclear Industry

Similarly, MIT’s study shows that

“Nuclear power is frequently cited as a critical component in the portfolio of technologies aimed at reducing greenhouse gas emissions. But rising construction costs and project delays have hampered efforts to expand nuclear capacity in the United States since the 1970s.”

Importance of forensic delay analysis

If we combine the elevated capital costs of nuclear plants, with the excessive and unplanned expenditure incurred by companies during COVID-19, we can all foresee a delay to start new projects, a delay to complete current projects, potential energy related bankruptcies, and certainly some contract cancellations.

Having said the above, we have written this article in order to illustrate some of the key characteristics that need to be accounted for when performing delay analysis in construction contracts.

To start with, the most appropriate approach to time and delay analysis is one which provides answers to the following questions:

- What was planned?

- What actually happened?

- What was the critical delay actually incurred? and

- Which events / issues actually caused delay to the critical path?

The understand the basics of these, we need to define some key and important terms.

Critical delay

Critical delays are delays to activities that can be said to have actually caused delay to completion of a project. Any delay of an activity on the critical path directly impacts the planned project completion date, as there is no ‘float’ or ‘slack’ on the critical path of a project.

The critical path is the longest sequence of activities in a project plan which must be completed on time for the project to complete on due date. In essence, the critical path is comprised only of critical activities, that, of the many that comprise a project, are considered “critical” because of their effect on total project time.

Figure 5 – Forensic Schedule Analysis – Critical Path

Non-critical delays are delays to activities that are not on the critical path, retain float, and have no causative impact on completion of a project.

Concurrent delays are delays where a project is delayed by two events at the same time, and forensic analysis will establish the dominant cause of delay to the project.

So, in forensic delay analysis , we are (mostly) concerned with critical delays and near critical delays.

TYPES of Critical Path

Prospective critical path

- The forecast or forward looking critical path.

Actual critical path

- The contemporaneous critical path prevailing at different points in time during a project.

- May change relative to progress at site.

As-built critical path

- The longest sequence of activities through the as-built Schedule

- Ignores float and relative progress during the project.

- May differ from the actual critical path.

APPROACH to Delay Analysis

Modelled methodologies

- Rely on computer software simulation to model the impact of pre-defined delay events (e.g. Primavera P6).

- Looks at potential causes and tries to establish the effect.

- It is Dynamic.

Observational methodologies

- Rely on the “discovery” of delays through investigation of project records and interrogation of the schedules (if available).

- Looks and the effect and tries to establish its cause.

- It is typically Static.

DETERMINATION of the Critical Path

Prospective

-

- The forward looking critical path, based on the plan for remaining work.

Contemporaneous

-

-

- The actual critical path prevailing in a period of, taking into account current progress and strategy for the works (determined progressively through time).

-

Retrospective

-

- The critical path determined based on as-built durations plus its sequence. May differ from the contemporaneous critical path.

Now, when we discussed about claims and dispute resolution, we consider that a Delay Expert must not only look at the face value of schedules, and to interrogate its activities, but the forensic schedule analysis also needs to consider all contemporaneous records available the Project (e.g. progress reports, minutes of meetings, correspondence), so that he/she can determine the true cause and effect of a delay event that actually affects the Critical Path of the Project – which can change during the course of the Project.

The Delay Analysis needs to be more of a fact-finding mission. It needs to provide an independent Expert opinion to help the Parties understand the details of how the Project actually evolved, what facts should be highlighted in order to explain the cause of a delay event, what would be expected from a Project Management perspective, what Variations or changes could have caused a time impact on the Project, what productivity issues were suffered by a Contractor (and why); and what elements contributed to the delay (or potential delay) in a Project.

As written by P. John Keane, Anthony F. Caletka in their book titled “Delay Analysis in Construction Contracts, 2 nd Edition”,

“The identification and assessment of delay entitlement can be difficult and time-consuming…. The purpose of delay analysis is to satisfy the causation requirement in such a way that it can be used to assess the resulting damages”

The Society of Construction Law provides a good guide for the best methodologies to be used in construction disputes, especially on the quantification of delays.

“ The object of the Protocol is to provide useful guidance on some of the common delay and disruption issues that arise on construction projects, where one party wishes to recover from the other an extension of time (EOT) and/or compensation for the additional time spent and the resources used to complete the project. The purpose of the Protocol is to provide a means by which the parties can resolve these matters and avoid unnecessary disputes. A focus of the Protocol therefore is the provision of practical and principled guidance on proportionate measures for dealing with delay and disruption issues that can be applied in relation to all projects, regardless of complexity or scale, to avoid disputes and, where disputes are unavoidable, to limit the costs of those disputes. On certain issues, the Protocol identifies various options, with the choice of the most appropriate being dependent on the nature, scale and level of complexity of a particular project and the circumstances in which the issue is being considered. On other issues, the Protocol makes a recommendation as to the most appropriate course of action, should that be available ”.

The Protocol shows a view of how to deal with core principles, such as Extensions of Time (EOT), programmes (schedules), effects of Delay, Concurrent Delay, Acceleration, Global Claims, Disruption Claims, Float, Valuations, and others.

Expert views

We understand that derailed Projects may not have all records as we would wish to have them, therefore, the experience of the Expert becomes quite important when performing an analysis with the limited or sometimes inaccurate information. This (between other factors) would affect the type of methodology that Delay Experts have to follow, which normally takes the following approaches:

- Planned vs. Actual (total time approaches);

- As Planned ‘impacted’ analysis;

- Collapsed as built analysis;

- Time impact analysis;

- “Windows” or “watershed” analysis.

The method depends on:

- A Retrospective vs. Prospective Analysis;

- Particular requirements of the contract;

- Value of the dispute;

- Time available;

- Records available; and

- Programme information available.

The methodology used needs to be chosen by the Expert(s), and ideally if there are Experts assigned by each Party, then they both need to agree on a methodology so that their respective analysis and conclusions can be easily interpreted and compared by others (e.g. members of the Tribunal). This is usually around a well favoured Windows Analysis.

The Forensic Delay Experts should be assigned depending on the type and complexity of the Project. This is great importance given that a Delay Expert not only needs to know about scheduling and methodologies, but really needs to understand the Industry and technical aspects of the Project under dispute.

The Experts need in many instances to be supported by forensic engineers and associates in order to review and understand the different technical issues encountered in a project. In such way, a full rounded opinion may be provided which is of greater use for the dispute resolution process. However, any expressed opinions that are not the Experts’ own, need to be clearly identified in their reports, as well as any assumptions made.

Final remarks

The best time to instruct a Forensic Delay Expert is as soon as it is practicably possible. In fact, this is more true in the current circumstances where we see a surge in claims worldwide, and the potential for conflicts of interest will increase, leaving out many experts and especially large organisations. We should, however, not forget that a Delay Analysis needs to be produced in a way that helps the Judges or Arbitral Tribunal in understanding the case, the Parties’ positions, and to allow them to make a decision based on factual information complemented with Expert opinion.

COVID has had its toll on society, on governments, and certainly on construction projects. Forensic Delay Experts will be able to bring clarity to potential disputes where schedules have been affected on the back of COVID related claims, and it is the Forensic eye that needs to drive major disputes into conclusion by following correct methodologies and experience.

London 26 th February 2021

DAC Consulting Services Ltd

The post Forensic Delay Analysis on the back of COVID related claims appeared first on DAC Consulting.

Industries We Serve

DAC Consulting Services is proud to work with clients across a diverse range of industries.

Our tailored approach ensures that we meet the specific needs of every sector we serve

Oil & Gas

Supporting upstream, midstream, and downstream operations, we offer

expertise in pipeline disputes, offshore projects, and refinery challenges.

Power Generation

From traditional coal and nuclear facilities to modern renewable energy projects, we provide expert insights and technical support for efficient power generation.

Renewable Energy

As the world transitions to sustainable energy sources, our team helps clients navigate the complexities of solar, wind,

and hydroelectric projects.

Construction

We specialise in large-scale public and private sector projects, including airports, bridges, metro systems, and urban developments.

Manufacturing

Our forensic engineering and dispute resolution services are critical for industrial and manufacturing facilities, ensuring operational continuity and efficiency.

Infrastructure

From transportation systems to public utilities, DAC supports infrastructure

projects that underpin communities and economies.

Get in Contact

We are committed to delivering excellence, ensuring clarity, and supporting your success.

Whether you need forensic engineering expertise, expert witness support, or assistance navigating the complexities of your industry, DAC Consulting Services is here to help.

Request a Consultation

Simply fill in the form below and one of our experienced team will contact you to discuss your requirement.

Contact Us

We will get back to you as soon as possible.

Please try again later.

London (HQ) Office

79a Grapes House

Suite 4, First Floor, Esher

Greater London

United Kingdom

KT10 9QA

Business Hours

- Mon - Fri

- -

- Sat - Sun

- Closed